Carbon Filter Cartridge Making Machine: Revolutionizing the Filtration Industry

John

- 0

Are you curious about how carbon filter cartridges are made? Look no further! In this article, I will introduce you to the fascinating world of carbon filter cartridge making machines and their role in revolutionizing the filtration industry.

The Carbon Filter Cartridge Making Machine: A Marvel of Engineering

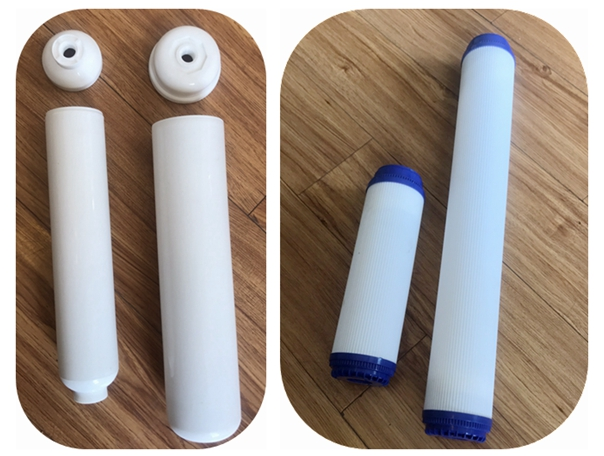

The carbon filter cartridge making machine is a state-of-the-art piece of equipment designed to produce high-quality filter cartridges efficiently. It combines advanced technology with precision engineering to create filters that effectively remove impurities from water and air.

This machine utilizes activated carbon, which has a large surface area capable of adsorbing contaminants. The process begins by feeding activated carbon into the machine’s hopper, where it is then evenly distributed onto a conveyor belt.

As the belt moves forward, an automated system ensures that the activated carbon is tightly packed into a cylindrical shape. This compacting process guarantees optimal filtration performance by maximizing contact between water or air and the activated carbon particles.

To enhance durability and prevent any potential leakage, specialized sealing techniques are employed during production. These ensure that every cartridge meets strict quality standards before being packaged for distribution.

The Filter Cartridge Winding Machine: Precision at its Finest

In addition to the main carbon filter cartridge making machine, there is another crucial component involved in producing these filters – the filter cartridge winding machine. This device plays a vital role in creating sturdy outer casings for each cartridge.

The winding machine operates by wrapping layers of polypropylene or other suitable materials around the compacted activated carbon core. This process not only provides structural support but also acts as an additional barrier against contaminants trying to bypass filtration.

Precision is key when using this winding machine, as any inconsistencies in the winding process could compromise the filter’s integrity. Therefore, advanced sensors and automated controls are employed to ensure uniformity and accuracy during production.

Once the winding process is complete, each cartridge undergoes rigorous testing to verify its filtration efficiency and durability. Only those that meet or exceed industry standards are deemed suitable for use.

Hongteng: A Leader in Carbon Filter Cartridge Making Machines

When it comes to carbon filter cartridge making machines, one name stands out – Hongteng. With years of experience and a commitment to innovation, Hongteng has become a trusted provider of these cutting-edge machines worldwide.

Their carbon filter cartridge making machines boast advanced features such as precise control systems, high-speed production capabilities, and user-friendly interfaces. Moreover, Hongteng offers customization options tailored to specific filtration needs.

By collaborating with clients from various industries, including water treatment plants and air purification companies, Hongteng continuously improves its machines’ performance while adapting them to evolving market demands.

In Conclusion

The carbon filter cartridge making machine plays a crucial role in producing efficient filters that remove impurities from water and air. Combined with the precision of the filter cartridge winding machine and the expertise of manufacturers like Hongteng, these machines have revolutionized the filtration industry by providing reliable solutions for cleaner environments worldwide.